People don’t like clash detection. It can be a reactive, tedious process. There will surely be a lot of innovation in this space over the next year, because there has got to be a better way.

In the interim though, how can we establish a rough guide of which disciplines do what, when? How can we apply common sense principles to this, so instead of being rigid, it’s flexible and focuses coordination efforts where they are the most valuable?

We’ve covered some important project set-up steps before for improved coordination and model quality. In this blog post, we will share one important tool that our parent company BIM One applies to their projects: the coordination matrix.

Establishing a coordination matrix

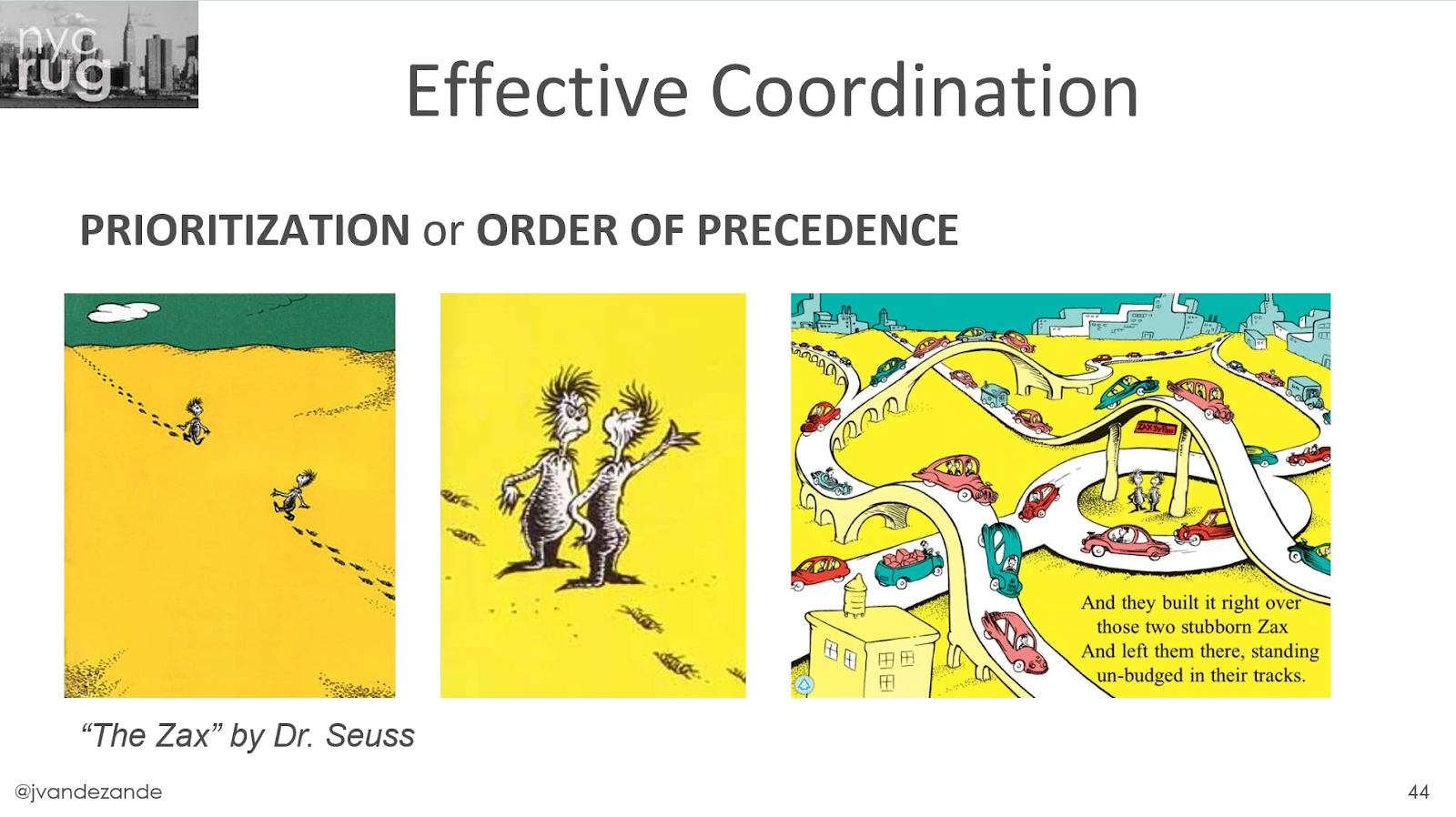

James Vandezande from HOK shared a great analogy about why prioritization of disciplines is important in this part of his NYCRUG presentation from a few months ago. You really do not want to be the project that builds around two stubborn Zaxes.

Figure 1.0 Why construction prioritization or order of precedence matters. Source: https://vimeo.com/238213778?ref=em-v-share

Figure 1.0 Why construction prioritization or order of precedence matters. Source: https://vimeo.com/238213778?ref=em-v-share

Your team probably already has a good understanding of which trade takes priority over which and in what order coordination is done. In our projects, we take the time to lay this out clearly in a coordination matrix. It’s not only a great way to make sure everyone is on the same page; it’s the starting point for managing your coordination deadlines. And the Zaxes would have known exactly who had to budge.

So what does it look like and what does it mean?

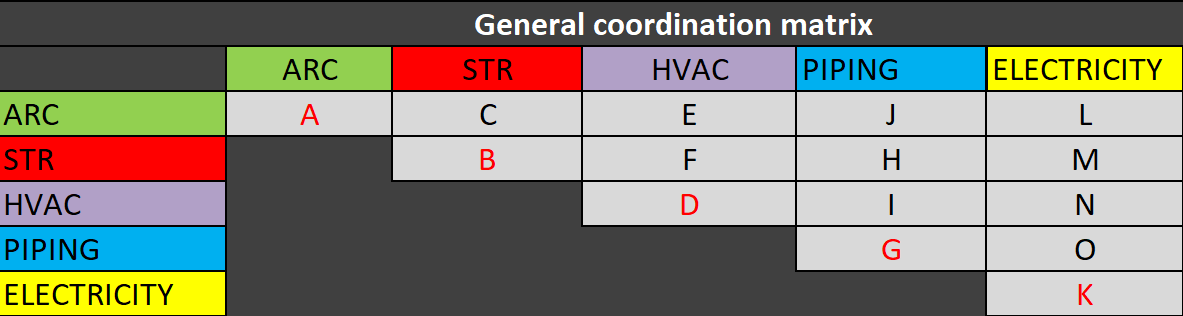

Figure 2.0 The coordination matrix is a tool for establishing coordination priorities.

In the coordination matrix above, each trade is responsible for their internal coordination as shown in the red letters above (ex: A = Arc vs Arc). For each letter, there has to be a coordination lead and a logic for who needs to modify their design, which may still need to be modified for certain cases. If the responsibility for clash detection is shared between stakeholders, architecture should ideally be responsible for their complete row and the other disciplines, their respective columns, even if there are redundancies.

The alphabetical order of the letters denote the order in which coordination happens. You can also create copies of this matrix and create a calendar for when internal coordination models are due and another for when coordination reports are due. The general coordination matrix helps to organize your clashes, and ensures major elements are addressed before the minor. This way you don’t coordinate electricity twice during a project because fire protection had to move because of structure, for example.

Now this is the way it worked out for this particular project at the beginning and it is definitely not a rigid framework. A lot can change depending on your project or coordination phase. For instance, you may have one firm responsible for modeling all MEP during the design phase so they will run coordination on those models simultaneously, while still respecting the overall priority of the sub-trades they are responsible for. But during construction phase coordination, each of those trades may take responsibility for the models so the dates their phases are due and the order in which they are coordinated may be different. We strongly recommend sub-matrices based on work packages.

Speaking of phases, you’re not going to clash electricity against joists during the design phase, for instance, because those aren’t yet designed for fabrication. Let’s apply our common sense. Wouldn’t it be nice if we knew exactly what we should clash against for each phase? Enter:

More matrices!

Rest assured, the Matrix does not have you. We’re going to show how by going into a second, even more granular level of planning, you actually end up only working on the clashes that matter.

We’re going to write down what categories we’re going to clash with what for each disciplines. We’ll even eventually set specific tolerances by category and preset our clash tests (.xml). Again, make it particular to the phase. How does this help? We’re avoiding silly, time-wasting clashes like moveable furniture against structural elements.

Here’s an example using a couple of groups from our initial matrix:

Figure 3.0 The secondary coordination matrix identifies precisely what will be coordinated / clashed against (visual inspection and automatic clash detection).

Figure 3.0 The secondary coordination matrix identifies precisely what will be coordinated / clashed against (visual inspection and automatic clash detection).

The massive grain of salt you need to take with these matrices

The matrices can and should change as the project evolves; they’re a tool to be used, not set in stone and make you curse the day you created it.

For example, if during construction work packages are changed and some categories of objects are not included anymore, the matrices should be amended based on the new deliverables.

Clash detection time

We don’t want to get into clash detection methods too much in this article. However, we would be remiss not to quickly mention:

- Visual inspection is still the first step to assessing issues, as anyone who has come across 2000 clashes in Navisworks or Solibri can attest to.

- When you do get to the automatic clash detection stage, be sure to use intelligent clash grouping tools like Group Clashes by BIM 42.

- Search sets: allows you to select objects by category (or other properties) to better define the clashes we want to detect (as defined in our secondary matrix ;-)). We recommend BIM Cave’s Auto Search sets.

Another way to run clash detection

Take the blue pill and call it a day if you have learned enough to apply to your projects.

But take the red pill and see how deep the rabbit hole goes.

There are other ways to review clashes more efficiently than a lengthy list. A heat map is one of those. A simple way to do this in Navisworks is by turning on all clashing objects for a moment. Instead of reviewing pointless clashes one by one, this helps you see the areas that have the biggest potential impact on cost. The teams can then focus their coordination efforts on these critical areas. We’ve also heard great things about this method from BIM Track client Aurecon, as presented by Kevin Thickett and team at BILT ANZ this year.

Have fun with your matrices

We hope the coordination matrices give you some solid tools to help clarify the coordination process within your teams and give a clear coordination action plan. Have any questions or feedback? Please contact me below.